Xchanger – Powered by Loxone

Xchanger

Collison Electrical Services have proudly been carrying out the electrical installation for Xchanger systems in dairies across the UK since early 2018. From Pembrokeshire to Edinburgh farmers have been opting for a greener, smarter solution to their parlour cooling systems – consisting of a heat pump essentially operating in reverse.

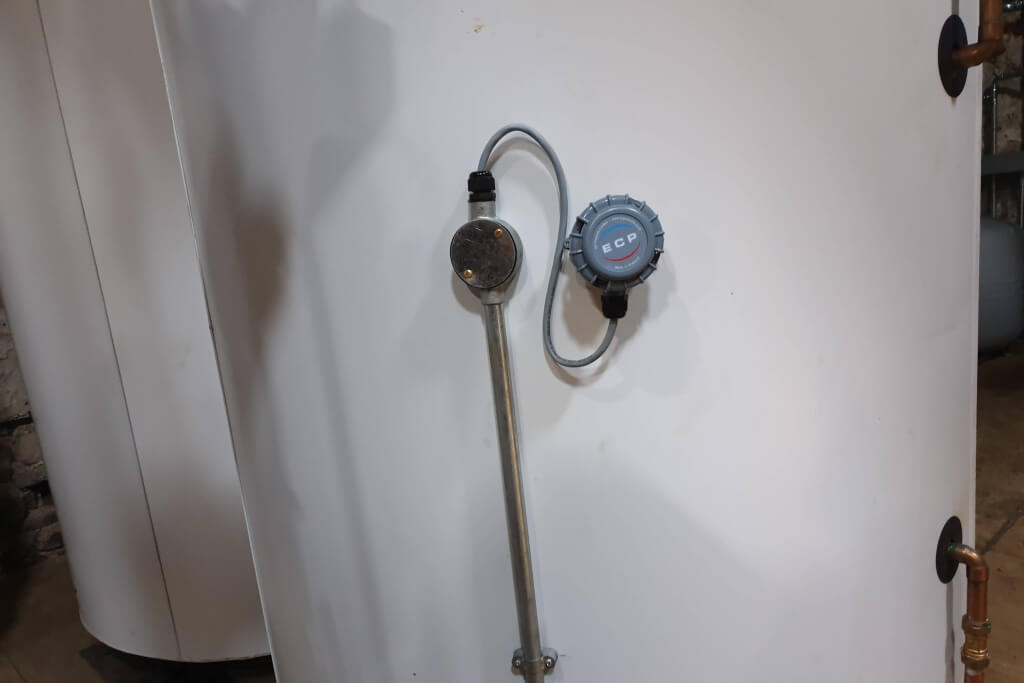

The basic principle of the Xchanger system is to cool the herd’s milk by removing the heat and dumping it into buffer storage tanks (large cylinders of water). The heat is then transferred into the parlours in the form of blow airs (essentially a heating fan) or sent to local domestic dwellings to supply underfloor heating and central heating systems. Farmers are currently incentivised to install the technology by claiming on renewable energy tariffs such as the Renewable Heat Incentive (RHI).

Facts

First project: Early 2018

Loxone powered Xchangers to date: 4

Projected Loxone powered Xchangers by end of the year: 22

Loxone Partner: Collison Electrical Services

After installing just a small number of the Xchanger units it became evident to the guys at Collison that as brilliant as the technology was it was lacking in functionality, such as remote access and control of the external heating equipment; so they turned to Loxone for a smarter solution.

Xchanger were unhappy with the lack of remote maintenance available to them – being based in Shropshire but with contracts up to 300 miles away it was important any faults or errors the Xchanger would come across could be immediately diagnosed and resolved (where possible remotely.) With Collison’s know-how, this was a simple fix. Each heat pump contained an alarm call which they were already using for a local beacon which alerted the farm manager of alarms. Leaving the beacon in place they utilised the same signal to send both a push notification (to use in the Loxone app) and an e-mail to the Xchanger head office. The Xchanger alarms consist of soft and hard alarms with soft resetting themselves and hard needing a manual reset – by adding some simple logic they were able to set up an additional e-mail notification to alert when the alarm is reset allowing the engineers to determine how serious the actual fault in question is.

The Xchanger management team wanted to be able to keep an eye on electrical consumption and the amount of heat energy produced. Using comms ready consumption meters they were able to take a pulsed output and let Loxone make its own consumption calculation – each pulse equates to ‘X’ amount of units of energy which is set dependant on the meter used. By adding this logic to the Loxone app the Xchanger team can now instantly see the power used in real-time at any site anywhere in the world along with the total heat produced – which is used when claiming against the RHI.

Heating and cooling circuits are now also managed by Loxone with thousands of setups and opportunities available to the Xchanger team ranging from simple commands to bring a cooling pump on, to automated heat dumping. These setups are very much site dependant but with the vast range of relays and inputs available on the Loxone Miniserver, most needs are met. When a more specific system is required Loxone’s plug and play extensions sit nicely inside the existing enclosures. Where required the farm owners are also given user-specific applications to enable them to remotely manage their heating circuits – this allows them to heat the parlour before milking on a frosty morning or boost the underfloor heating for an extra hour all from their smartphones.

Looking to the future of the Xchanger-Loxone smart system the team at CES are already working on integrating the Xchanger ModBus communication system which will enable the team direct access to the heat pumps with the ability to read specific alarms, monitor flow and return temperatures, read system logs along with a host of other benefits. In addition to this, they’ll also be utilising the same ModBus communication language but linked to the consumption meters – this will reduce any inaccuracies and duplicate the exact figures as on the front screen of each consumption meter.

As mentioned throughout, this project was completed by Collison Electrical Services using Xchanger systems. You can head over to their websites to find out more or if you’d like to learn more about Loxone being used in commercial environments click below.