The Nano Motor Controller Air is a compact module with DC outputs, controlled via the Loxone Air technology.

Its configurable outputs allow the control of DC motors or LEDs in the following operating modes:

Motor bidirectional: One output for DC motors with control of direction and speed.

Motor unidirectional: Two outputs for DC motors and speed control, no direction change possible.

Dimmer: One output for dimming low voltage LED lights.

An internal H-bridge is used to switch the outputs and reverse their polarity. Motor speed and dimming are controlled through pulse-width modulation.

Datasheet Nano Motor Controller Air

Table of Contents

- Mounting

- Commissioning

- Operating modes

- Notes on operating motors

- Set current threshold values

- Inputs, Outputs, Properties

- Safety Instructions

- Documents

Mounting↑

Install the device in a suitable installation box.

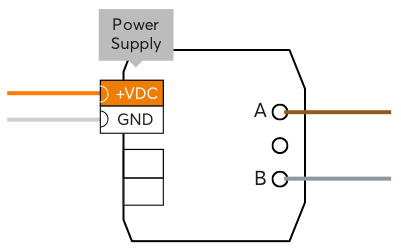

Connect the power supply (orange/white screw terminals).

The supply voltage will depend on the load, but must be in the range of 9...26VDC.

The selected operating mode specifies how the outputs are connected.

Commissioning↑

In delivery state, pairing mode will be active after the power supply has been established. This is indicated by the status LED flashing red/green/orange.

Then follow the pairing procedure on the Air Interface.

To activate the pairing mode manually, switch off the power for 10 seconds, then switch it back on. If no connection to a Miniserver can be established for two minutes, then pairing mode is activated for 30 minutes.

Operating modes↑

The Nano Motor Controller supports three operating modes that can be set in Loxone Config. They differ in function and how the outputs are connected:

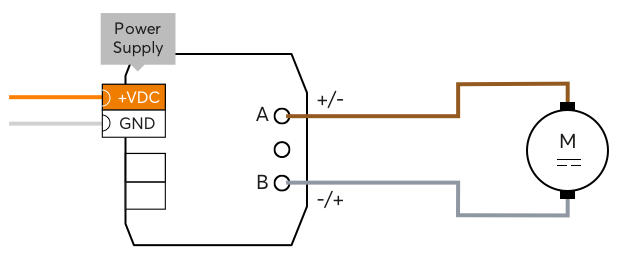

Motor Bidirectional

This operating mode provides one output for DC motors with control of direction and speed.

The rotation direction can be changed by the Nano Motor Controller by reversing the polarity of the outputs:

This is useful for applications where a change of rotation direction is required, e.g. motors for shades, curtains, or motorized windows.

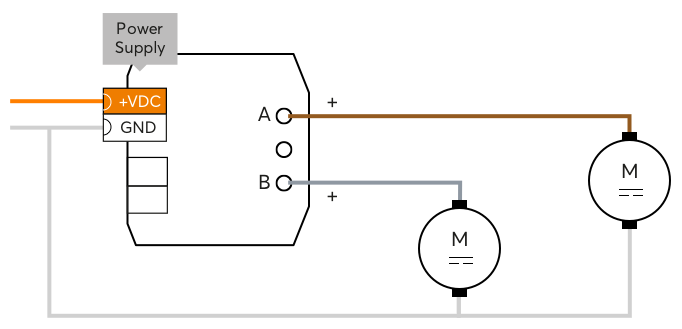

Motor Unidirectional

This operating mode provides two output for DC motors with speed control, the outputs are independently controllable.

The rotation direction is determined by the connection:

This is useful for applications where two motors are to be controlled separately.

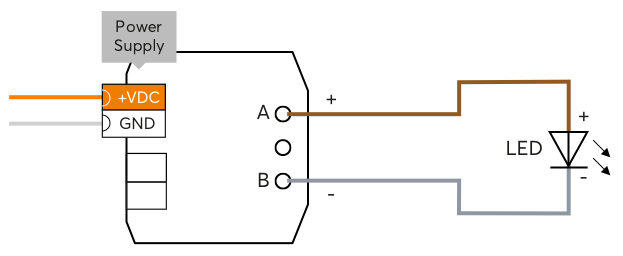

Dimmer

This operating mode provides one output for dimming low voltage LED lights:

This is useful for lights like LED strips or spots that operate at a constant voltage, e.g. 12V or 24V and can be dimmed by pulse width modulation (PWM).

Notes on operating motors↑

The speed and direction of motors are controlled directly via their supply voltage.

The voltage at the outputs of the Nano Motor Controller is pulse-width modulated to control speed, and in bidirectional mode it reverses polarity to change the direction.

True DC motors, that have a commutator and brushes, are especially well suited.

Brushless DC motors are often equipped with an internal controller which makes control of the motor speed via PWM control of the supply voltage impossible.

Such motors can only be switched on or off. The speed must be set to 100%, the acceleration value can be set to Jump.

Reversing the rotation direction is often not possible, and there is a risk of damaging the motor electronics if it is not designed for changing the direction and does not have reverse polarity protection.

Connecting motors in parallel to one output is only possible under certain conditions.

It must be ensured that only motors of the same type are used, and that they are equally loaded.

The overcurrent shutdown of the Nano Motor Controller may trigger despite a high overcurrent limit value when motors with a high moment of inertia start or decelerate (brake).

This can be avoided by decreasing the value for acceleration and braking to e.g. 20%/s in order to reduce the current drawn by the motor during start-up and deceleration.

During the first second of motor start-up, the set overcurrent threshold is ignored and is fixed at 5A. If this is too short, the overcurrent limit can be increased up to 5A to allow operation of motors with longer start-up times. The operation of motors in the overcurrent range of 2.2 - 5A is allowed for max. 30 seconds.

When stopping the motor it does not coast to a stop, but due to technical reasons the Nano Motor Controller applies a braking force.

If coasting to a stop without a braking force is desired, the value for deceleration must be set to a lower value, resulting in a more natural coasting.

Set current threshold values↑

From the Nano Motor Controller's properties you can open a diagram for setting the current thresholds:

A graph is drawn using the current drawn by the motor. The threshold values for current flow and overcurrent can be calibrated by performing a test run of the motor or drive used.

It is recommended to not set the threshold values too close, in case the motor load and current draw changes somewhat due to wear or temperature influence.

The values are then applied by saving the program to the Miniserver.

Sensors↑

| Summary | Description | Value Range |

|---|---|---|

| Current Flow | Input activates when the current drawn by the motor is above the threshold value for current flow (bidirectional operating mode) | 0/1 |

| Overcurrent | Input activates when the current drawn by the motor is above the threshold value for overcurrent (bidirectional operating mode) | 0/1 |

| Current flow A | Input activates when the current drawn by motor A is above the threshold value for current flow A (unidirectional operating mode) | 0/1 |

| Current flow B | Input activates when the current drawn by motor B is above the threshold value for current flow B (unidirectional operating mode) | 0/1 |

| Overcurrent A | Input activates when the current drawn by motor A is above the threshold value for overcurrent A (unidirectional operating mode) | 0/1 |

| Overcurrent B | Input activates when the current drawn by motor B is above the threshold value for overcurrent B (unidirectional operating mode) | 0/1 |

Actuators↑

| Summary | Description | Unit | Value Range |

|---|---|---|---|

| Clockwise Rotation | Output activates the motor clockwise rotation A+/B- (bidirectional operating mode) | - | 0/1 |

| Anticlockwise Rotation | Output activates the motor anticlockwise rotation A-/B+ (bidirectional operating mode) | - | 0/1 |

| Start/Stop A | Output activates motor A (unidirectional operating mode) | - | 0/1 |

| Start/Stop B | Output activates motor B (unidirectional operating mode) | - | 0/1 |

| Speed | Output specifies the speed for the motor (bidirectional operating mode) If the output is not used, the default speed is used |

% | 0...100 |

| Speed A | Output specifies the speed for motor A (unidirectional operating mode) If the output is not used, the default speed is used |

% | 0...100 |

| Speed B | Output specifies the speed for motor B (unidirectional operating mode) If the output is not used, the default speed is used |

% | 0...100 |

| Dimmer WW | Standard actuator with one channel to control lighting (dimmer operating mode) | % | 0...100 |

| Smart Actuator WW | Smart Actuator WW to control lighting, use on compatible lighting blocks (dimmer operating mode) | - | - |

Diagnostic Inputs↑

| Summary | Description | Unit | Value Range |

|---|---|---|---|

| Online Status Nano Motor Controller Air | Indicates whether the device can be reached by the Miniserver. Diagnostics for Air devices Diagnostics for Tree devices Diagnostics for Extensions |

Digital | 0/1 |

| System temperature | Provides the internal device temperature. This is often the temperature of the CPU or another location in the device. |

° | ∞ |

| Temperature Shutdown | If the CPU temperature reaches a critical point, the outputs of the device are switched off. This can be due to short-circuits, overloaded switching loads or too high an ambient temperature. | Digital | 0/1 |

Properties↑

| Summary | Description | Unit | Value Range | Default Value |

|---|---|---|---|---|

| Monitor Online Status | When selected, you will be notified via System Status or the Mailer if the device is no longer available or goes offline. | - | - | - |

| Disable Repeater functionality | Disable repeater functionality of this Air device. Loxone Air is based on mesh technology. Any air device connected to the power supply can repeat packets from other Air devices, thus extending the range and stability of the overall system. In large systems with a large number of air devices in a confined space, the communication between the air devices can lead to a very high radio channel utilization. A reliable accessibility of the air devices can not be guaranteed. Disabling repeater functionality on individual Air devices can help. Do not disable this function recklessly as this may affect the range and stability of the system. |

- | - | - |

| Serial Number | Serial number of Air device | - | - | - |

| Device type | Air device type | - | - | - |

| Operating mode | Specifies the operating mode of the Nano Motor Controller. Motor bidirectional: One output for DC motors with control of direction and speed. Motor unidirectional: Two outputs for DC motors and speed control, no direction change possible. Dimmer: One output for dimming extra low voltage LED lights. |

- | - | - |

| Current threshold values | Configure the current threshold values using a graph of the measured current. | - | - | - |

| PWM frequency | Frequency of the pulse width modulation. Used to adapt to the motor. This can eliminate whistling noises, for example. | Hz | 1000...10000 | 5000 |

| Current flow threshold | Current flow is detected above this value. | mA | 100...5000 | 100 |

| Overcurrent threshold | When this value is exceeded, overcurrent is detected, the output switches off and the overcurrent input is activated. During the first second of motor start-up, the set overcurrent threshold is ignored and is fixed at 5A. The operation of motors in the overcurrent range of 2.2 - 5A is allowed for max. 30 seconds. (Motor start-up) The total current is relevant. |

mA | 100...5000 | 3500 |

| Speed up | Rate of change when powering on. Jump means that the target value is set immediately. |

- | - | - |

| Slow down | Rate of change when slowing down. Jump means that the target value is set immediately. |

- | - | - |

| Default speed | Default speed when the speed output is not used. | % | 0...100 | 100 |

Safety Instructions↑

The installation must be carried out by a qualified technician in accordance with all applicable regulations.

The installation requires a suitable enclosure to ensure protection against contact, water and dust.

Documents↑

Datasheet Nano Motor Controller Air