Brief: I need a preventive maintenance system.

A preventive maintenance system is considered the holy grail of maintenance systems. However, despite this, it’s not yet commonplace in commercial environments.

Typically, machines are maintained at regular intervals and repairs are carried out when the system reports major faults or has already failed. Predictive maintenance enables a much more efficient, condition-based approach.

Sensors record parameters such as vibrations. These are evaluated and, if necessary, compared with past data in order to draw conclusions about any necessary maintenance of the machine in question.

Preventive maintenance, therefore, involves monitoring the condition of machinery during operation to determine when it needs to be serviced.

By implementing a preventive maintenance system, maintenance and prepare work is only carried out when necessary – rather than on a set routine or schedule. This helps keep costs down as unnecessary maintenance is done. In this Use Case, we’ll show you how to set up a preventive maintenance system.

Solution: Using Loxone to create a preventive maintenance system.

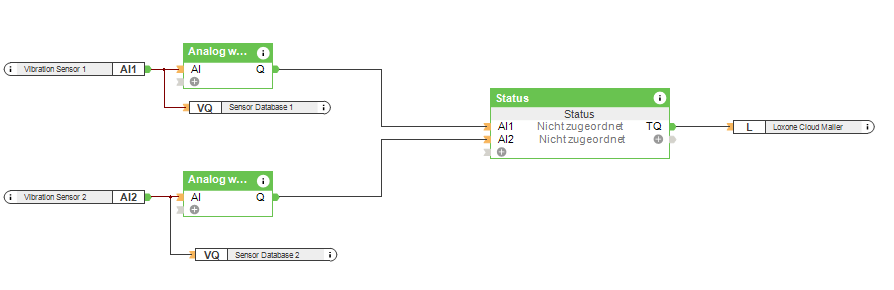

Sensors record the vibration data of machines, specific parts, etc. and thus provide information about the wear and tear and the stress on the machine. The data collected by the vibration sensors are evaluated by the Miniserver and visualized in real-time.

In the event of excessive deviations from the “basic vibration” of engines and systems, the person responsible for maintenance is informed by e-mail so that the necessary service and maintenance measures can be initiated or carried out promptly.

Hardware:

- Loxone Miniserver

- Vibration Sensor (Third Party)

Configuration:

Download the sample file:

Service Monitoring for Machines

Why you and your customer should consider implementing a preventive maintenance system?

If a machine completely fails, it can result in long and costly downtime. Which, obviously, negatively affects the productiveness of the workplace. However, this can be avoided by using a preventive maintenance system – as “issues” will be detected before they even become issues. Hence maintenance can be carried out and the machines can continue to get on with their job.