Drinking water production plant

Fact Check

Challenge

THIS CONTENT IS AUTOMATICALLY TRANSLATED BY GOOGLE TRANSLATE.We are a little proud of what has become of our first small project for monitoring, controlling and documenting a drinking water production plant.

Almost 10 years ago we equipped the first drinking water production system with a Miniserver. Since then, it has been doing its job reliably, providing information about faults, taking over the control tasks and transferring all the required measurement data to our data portal ***"WaterServer 2.0" for archiving.

Since then we have equipped almost 60 drinking water production plants with a #Miniserver.

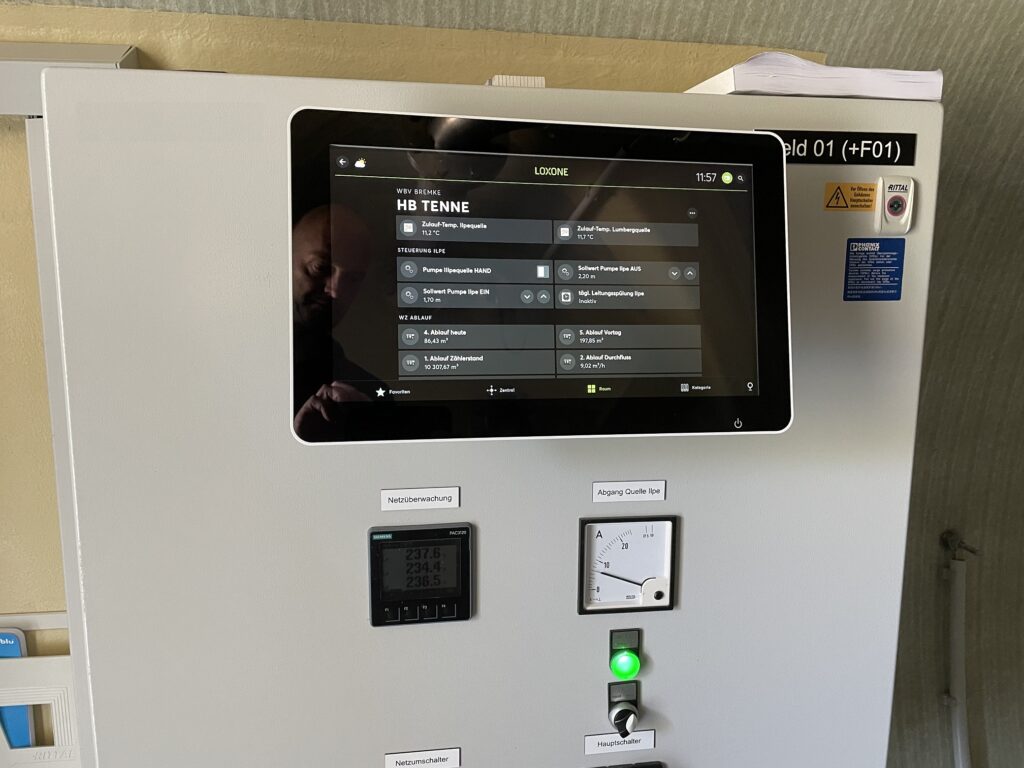

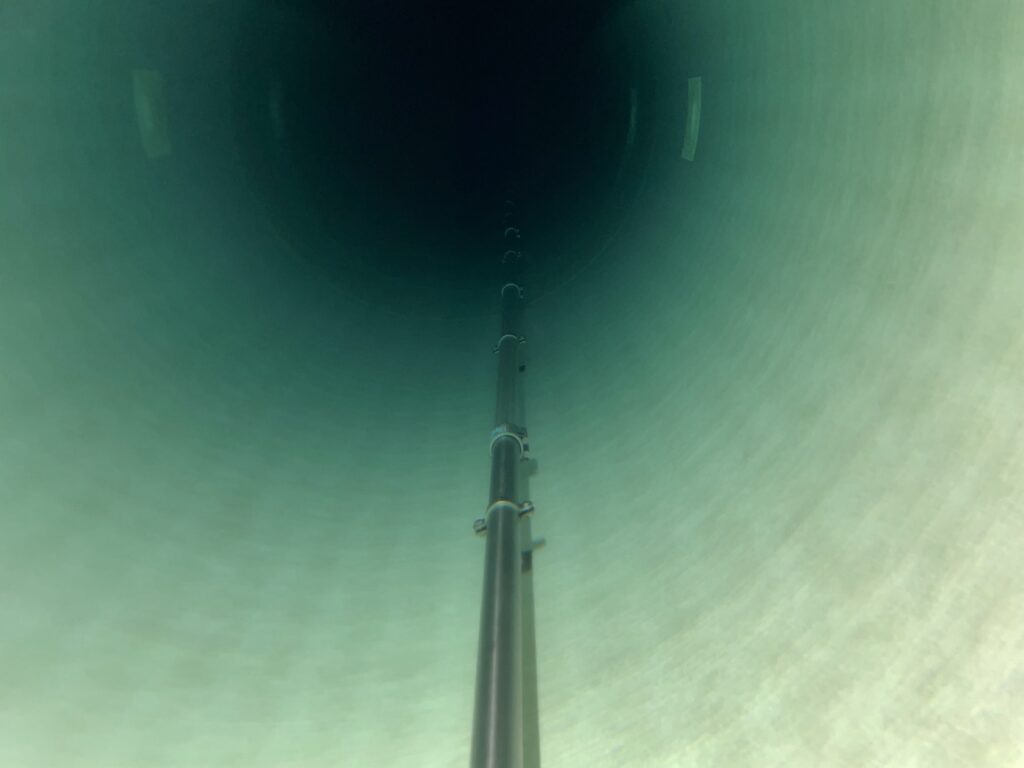

In the summer of this year, the new high-level drinking water tank of the Bremke water procurement association went into operation. The old elevated tank was converted into a pumping station.

An LTE router in the old elevated tank is used for long-distance data transmission. From there, a fiber optic cable was laid to the newly erected elevated tank in order to create a network connection between the two structures. Both mini servers are protected by a secure VPN.

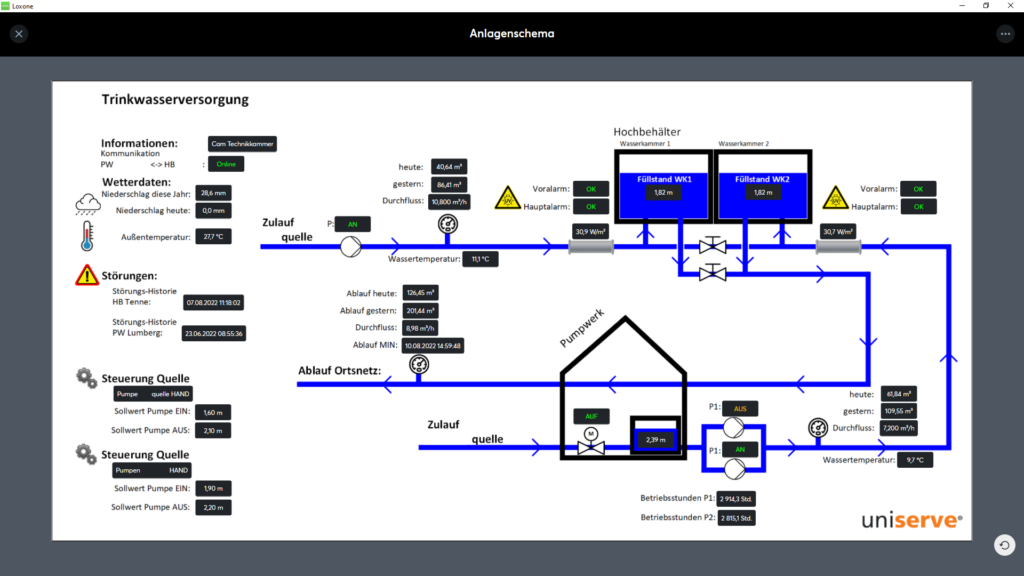

The task included, among other things:

- the control of pumps in 2 available sources

- an automatic pump change with each new request from the elevated tank

- keeping the line fresh if no request was made for one of the sources

- Adjustability of setpoints/system parameters via the app/visualization

- Alerting of fault messages to selected user group

- Recording and logging of measured values, such as temperatures, fill levels, meter readings, flow rates

- Video surveillance of the technical room

- Access control

- Visualization of the most important elements of the overall system in the system scheme

____________________________________________________________________________________________________________________

***The data portal "WaterServer 2.0" is a system recognized by various monitoring authorities for compliance with the documentation obligations resulting from the drinking water ordinance and the technical regulations (e.g. DVGW W127, DVGW note W1010).

Solution

THIS CONTENT IS AUTOMATICALLY TRANSLATED BY GOOGLE TRANSLATE.The Loxone Miniserver offers countless options for managing various tasks, functions and options for automation, and not just for buildings of all kinds. The network capability, the simple way of programming and the visualization offer everything that is necessary for an automation technology project.

THIS CONTENT IS AUTOMATICALLY TRANSLATED BY GOOGLE TRANSLATE.

Sven KramerProject Manager

A pilot project was started 10 years ago to monitor the fill level of a drinking water basin. Since then, this project has grown and expanded steadily. The reliability of the Loxone Miniserver, despite the high stress on the SD card and the sometimes harsh environmental conditions on site, have been convincing ever since. Even after almost 10 years, the Miniserver does its job just like on the first day. It offers a simple possibility for visualization in order to have a constant overview of all statuses.